In today's world, we have a lot of resources and materials for use. This is so because, in the recent world, science and technology has taken the lead and is now controlling the whole world. Globalization hasn't impacted something positive to some people yet. Now that we are living in a digital world full of many resources, various people have converted it to be their work. For you to make money, you need to be innovative and creative in that you can transform your ideas into something great which can be used by many people. This is so because the engineering field has been impacted positively by technology and thus the manufacture and production of many materials like plastics and metals. However, to know why the manufacturing industries such as Ionthis which have the design engineers should be hired to do most of the work if not all of it, the article below is a suitable guide for you.

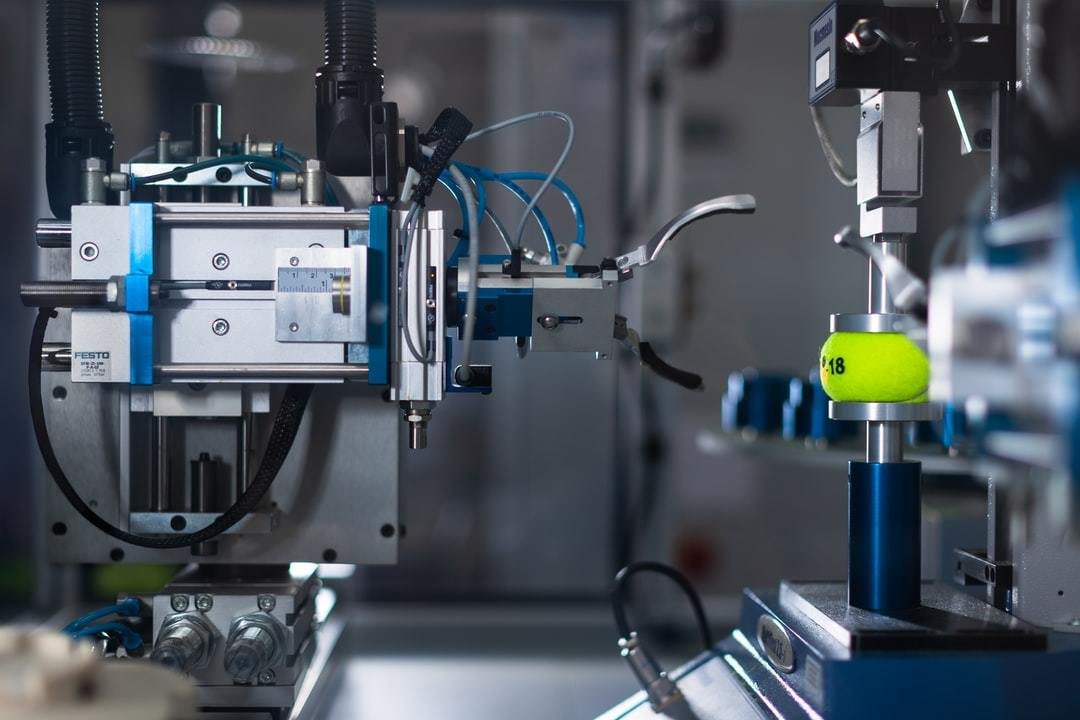

Most of the design and engineering manufacturing companies are known to have the best and well -trained employees. Majority of the companies should ensure that they train their staff to the maximum so that quality work and service are done to avoid losses and errors in the designed and manufactured products. Therefore, the managers of many contract manufacturing engineering companies should ensure that their workers don't fail them through the design of low-quality products. For that reason, engineering industries are very beneficial to the whole world.

For you to be qualified and be allowed to deliver your service to any client, you need a wide range of experience. Many workers of various manufacturing companies must have a lot of experience because it's just a repetition of the daily activities they do and so the experience is a must they gain. When you have the experience, you offer quality work to your clients. The design and manufacturing industries have the right people to attend to many clients.

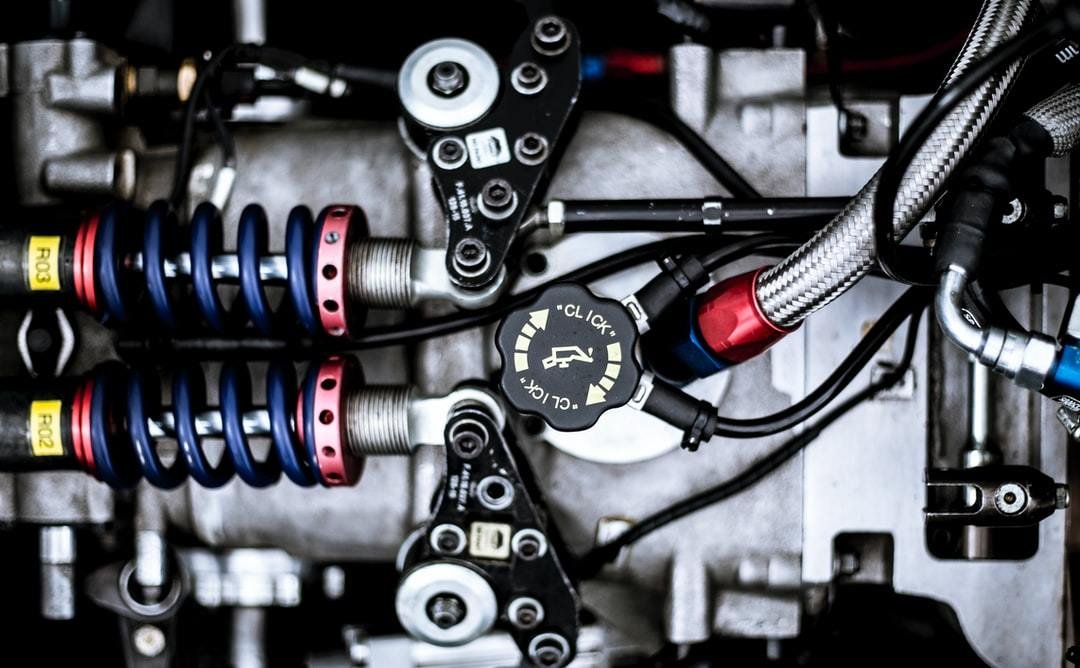

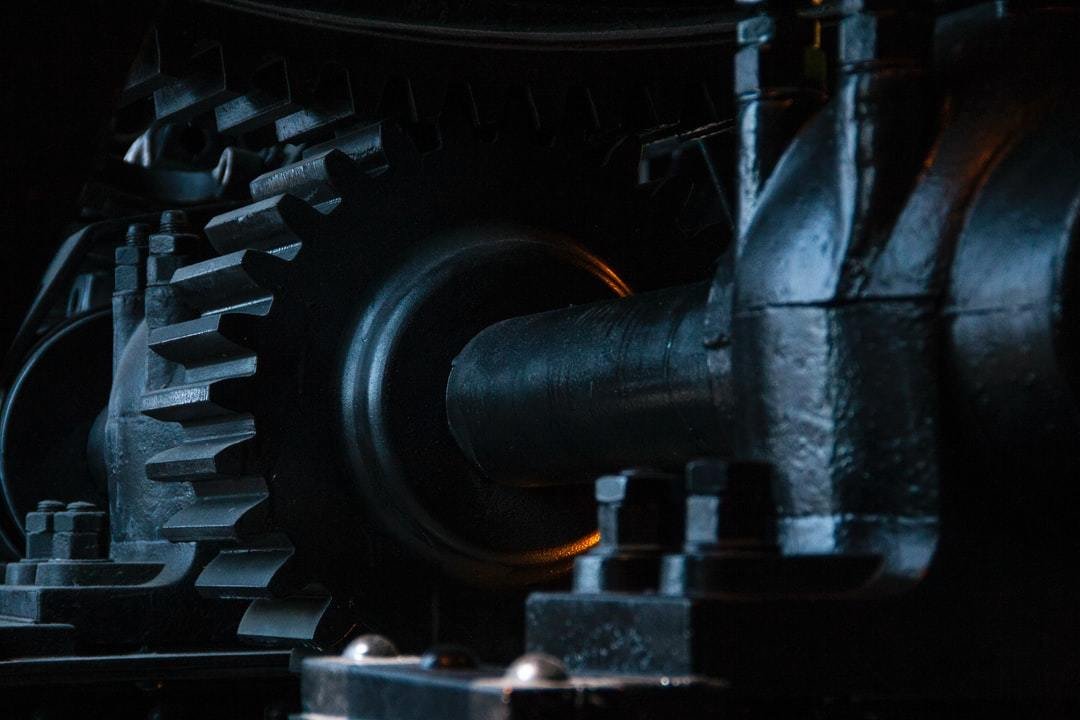

In addition, the design and manufacture high-quality products. High-quality products normally attract many customers and thus, your company will always be contacted for such services. The authorized manufacturing firms are quite beneficial in terms of their products. Explore more details here on why engineering companies should manufacture metallic and other silicone and plastic components.

Finally, these companies have staff who is supportive and very friendly. This has been seen regularly in terms of cost because many companies normally want to help their customers with fair costs of products. The article above talks on the advantages of using the design and manufacturing engineering firms.

Learn more about Mechanical engineering here: https://en.wikipedia.org/wiki/Mechanical_engineering.